How is Perfume Made?

Published: Jan 11, 2024 • Last Updated: Jan 10, 2024

The first thing you need to make a perfume are the scented ingredients of course. The ingredients are either

- Natural: Like Flower petals, Oakmoss, Sandalwood. They can be obtained from a variety of sources from across the world.

- Synthetic: Like Musk, Ambroxan, ISO E Super. Some of them were invented to do specific tasks, others were made to replicate their natural counterparts. Musk and Ambroxan for example used to come from animals and this caused over-hunting of endangered species. Governments placed appropriate bans to protect the animals and the scientific community created synthetic molecules that mimicked the scent and properties of those ingredients.

Natural Ingredient Extraction

When you receive a natural raw material, the first task is to convert it into a usable form. For this purpose there are several extraction methods used in the industry to obtain highly concentrated oils of the fragrant molecules from the ingredients.

- Solvent Extraction: You put plants in a giant rotating drum along with a solvent like petroleum ether or benzene. The plant eventually dissolves in the solvent leaving you with a waxy substance which is purified with ethyl alcohol.

- Steam Distillation: Steam is passed through the raw materials that extracts and carries fragrant molecules with it. This steam is then captured, cooled and distilled to obtain the concentrated perfume oil.

- Expression: This method has been in use for thousands of years. You mechanically press the plants until all of its oils are extracted.

- Enfleurage: Another very old and labor-intensive technique that is still in use today. They are useful to work with delicate flowers. The flowers are placed on a glass sheet with a fat coating. They are left on this glass sheet for hours or days until their aroma is absorbed into the fat. Then the fat is recovered and refined to obtain pure fragrance oil.

- Maceration: This is similar to Enfleurage but the flowers are soaked in heated oil instead of placed on a thin film of it. The oil absorbs the aromatic compounds and then it is purified.

Making Synthetic Ingredients

These days more and more ingredients are made synthetically instead of being sourced naturally. There are several reasons for this

- Natural ingredients like flowers are not available throughout the year

- Many ingredients are geographically limited and importing can get very expensive

- Over harvesting can do a lot of damage to nature and still not meet demands

- Synthetic ingredients are more stable and allergen free than natural ones

- Some notes can not be captured naturally like the smell of the ocean.

How these synthetic ingredients are made is a well kept secret of the perfume industry. All we can say is - Chemistry.

Designing a scent

A master perfumer aka "nose" has access to vials of pure fragrance oil of thousands of ingredients and this is where it becomes an art to combine several ingredients to create a perfume that smells like the perfumer's vision.

The nose will experiment by combining several ingredients in carefully measured quantities to create a "sketch" that represents the vision of the perfumer or the brief from the client if they are working for someone else. This can take several years and hundreds of ingredients!

Once the perfumer is happy with how their experiment smells like, they will draft a formula so that the perfume can later be mass produced in factories.

Testing and Permits

The perfumes go through several tests to make sure they are safe to use for humans and do not contain any banned materials according to the laws of relevant countries. The perfume companies have to obtain relevant permits and licenses from relevant licencing authorities to sell those perfumes in their country or region.

Manufacturing perfume

Once you have a formula to create your amazing perfume and the license to sell them, you can start the manufacturing process. These go as:

- Transporting perfume oils to the manufacturing unit. A perfume may require hundreds of ingredients that arrive at the facilities from all over the world or at the very least all over the country.

- Mixing all the ingredients in right proportions. Basically recreating the formula but all the quantities are sized up proportionally in multiple folds.

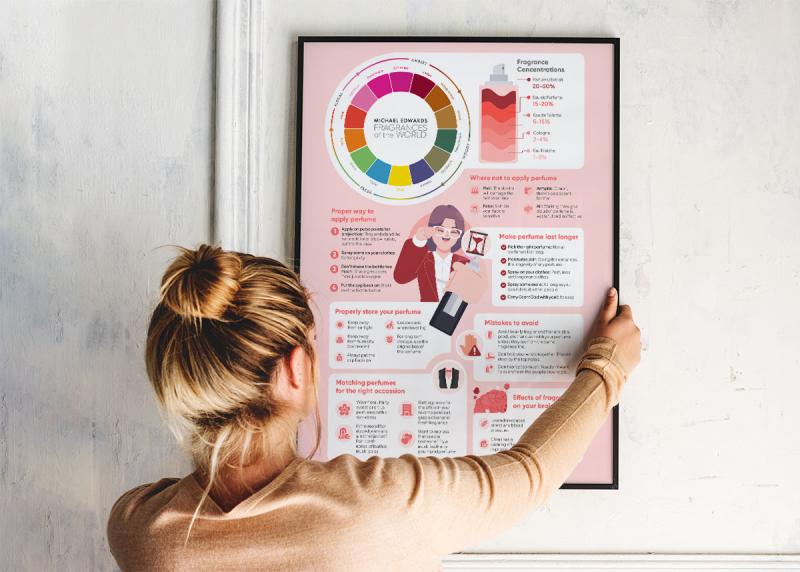

- Dilution. Most perfumes are delivered in an alcohol base that varies from 50 to 98% alcohol content. This determines the concentration of the perfume. We made an article on this if you want to understand different types of perfumes.

- Packaging. Finally a combination of machines and humans package the juice into attractive bottles and then boxes to be sold all over the world. Look at this fascinating video from WondasticTech to see this in action.

Never miss another article!

- - Get notified when we publish a new article.

- - No personal information required. Turn off anytime

Preet Singh

I have always been enamored by the power of perfumes to evoke emotions and capture memories. This profound love for fragrances led to the creation of ScentGod, a platform designed to allow everyone the luxury of discovering and wearing premium scents without the commitment of a full-sized purchase. My vision for ScentGod is more than just offering fragrances; it's about sharing passion, creating experiences, and helping people find their signature essence.

Read More